+86-19862000127

+86-19862000127

Synchronous belt

Synchronous belt

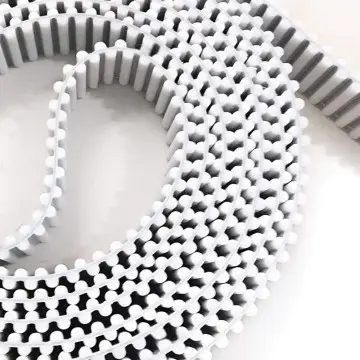

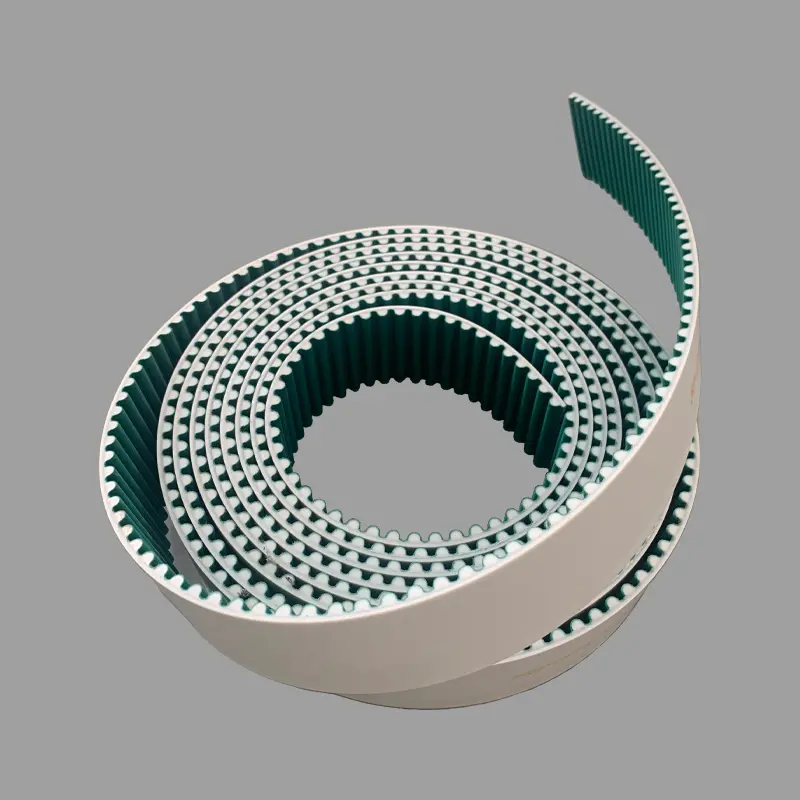

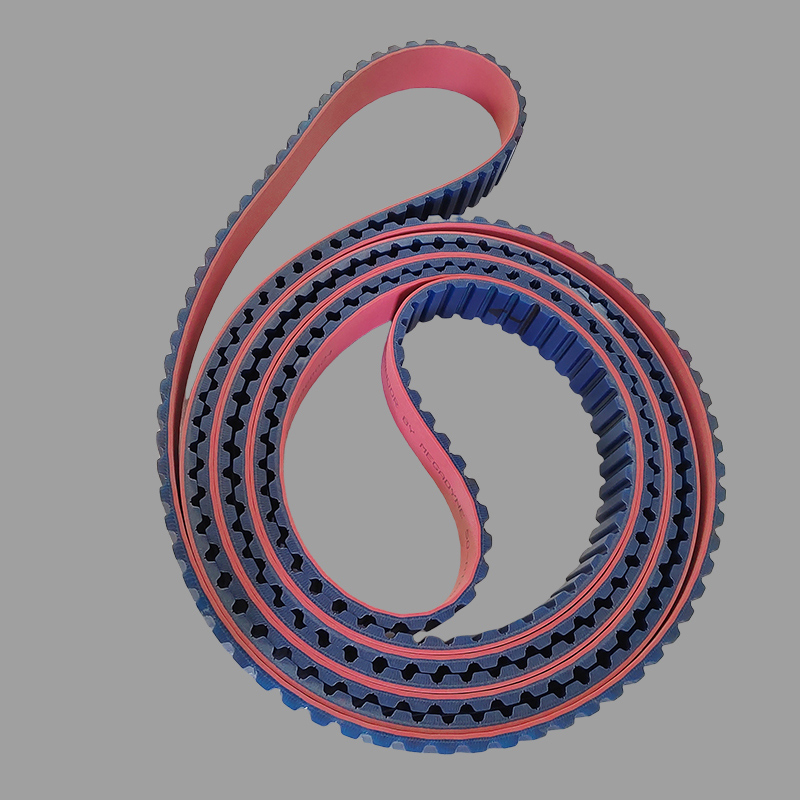

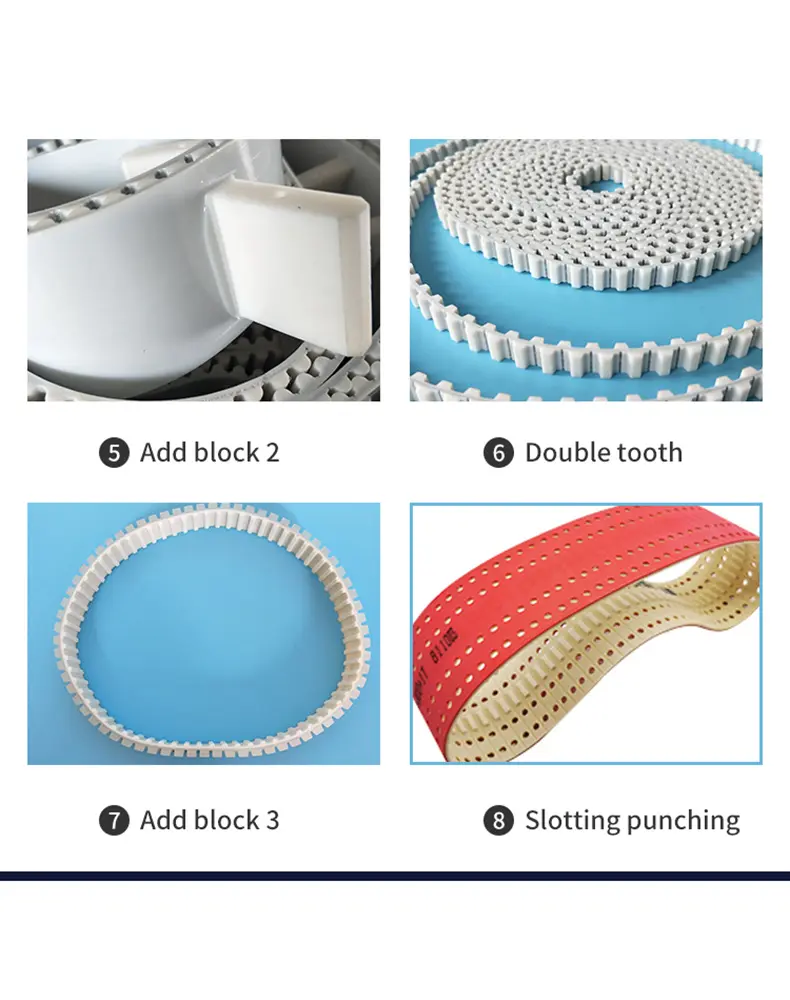

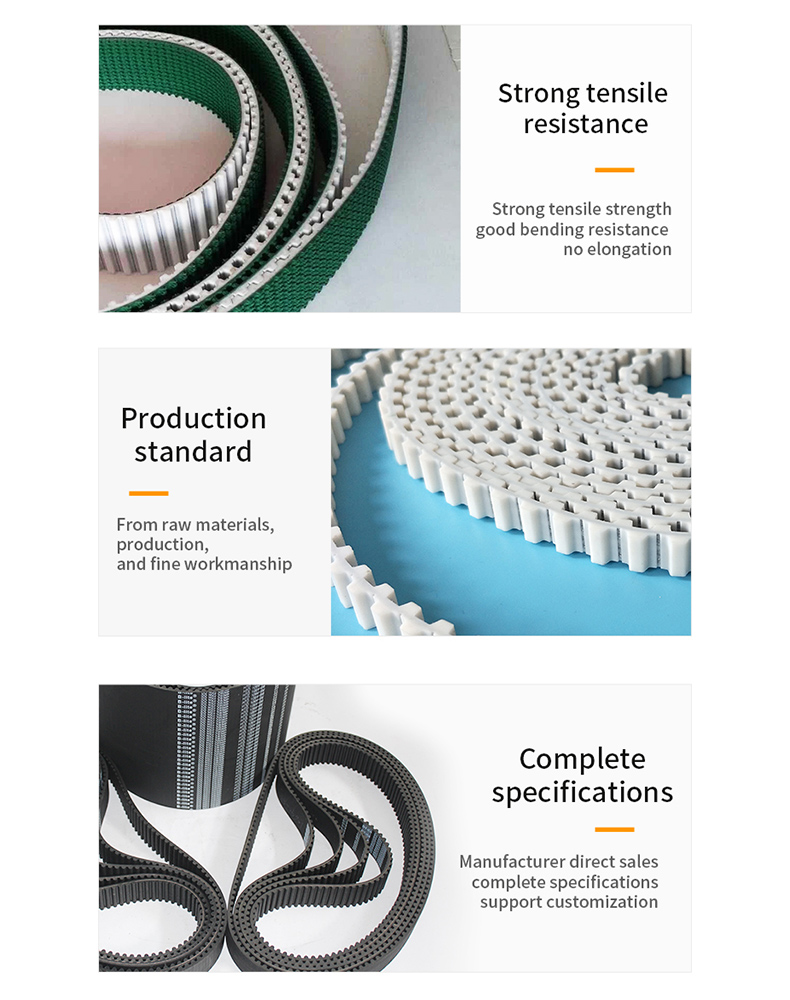

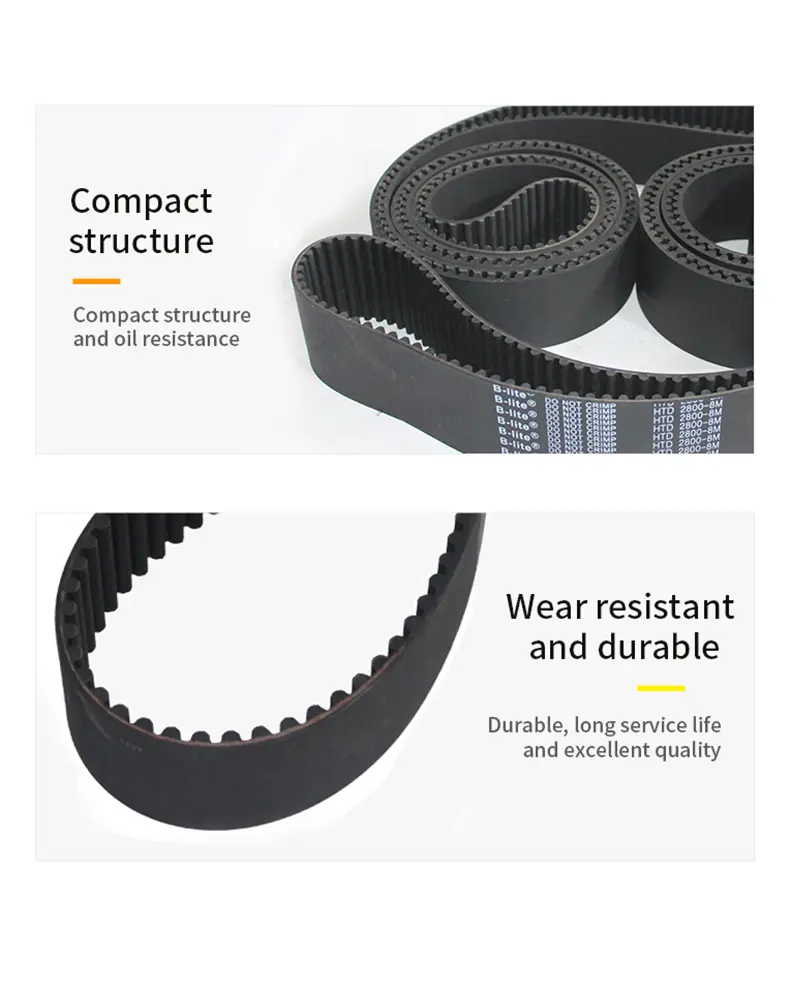

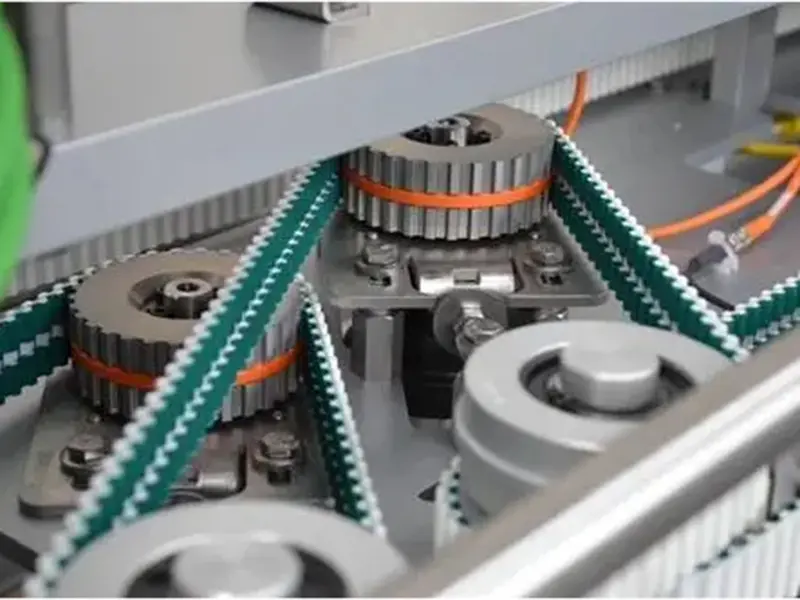

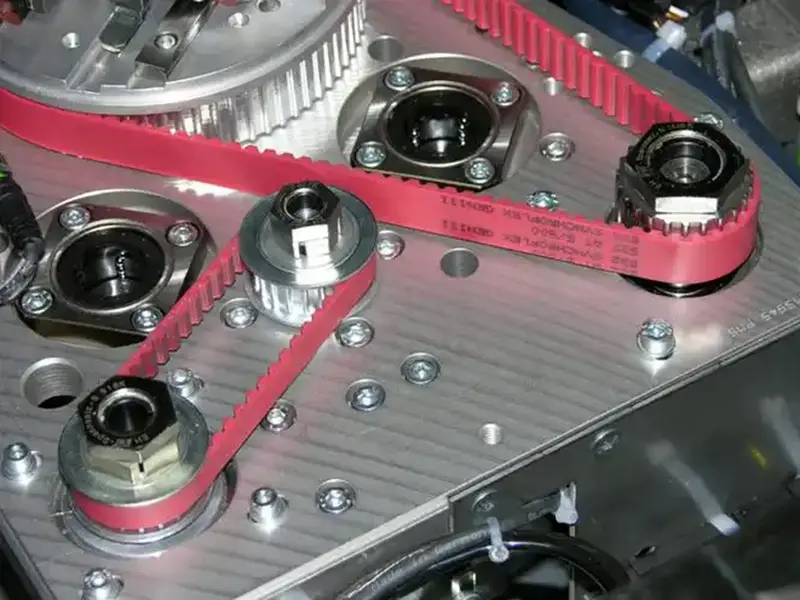

Synchronous belt, also known as toothed belt or timing belt, is an efficient and precise transmission device. It is made of steel wire rope or glass fiber as a strong layer, covered with polyurethane or chloroprene rubber, forming a circular structure. The inner surface of the synchronous belt is equipped with equidistant teeth, allowing it to precisely mesh with the toothed pulley for transmission, ensuring no relative sliding during the transmission process and thus maintaining a constant transmission ratio.

The synchronous belt consists of the following parts: strong layer, toothed layer, wrapping layer, and adhesive layer

The advantages of synchronous belts are as follows: high transmission efficiency, no slip characteristics, smooth operation, strong load-bearing capacity, and simple maintenance

Application areas of synchronous belts

Automotive industry: used for transmission of key components such as engines and transmissions

Mechanical manufacturing: widely used in power transmission systems for various machine tools, textile machinery, printing equipment, etc

Packaging machinery: used on automated packaging lines to drive conveyor belts, cutting devices, etc

Logistics industry: used to drive stacker cranes and conveyor lines in automated three-dimensional warehouses

Agricultural machinery: providing power support on large agricultural machinery such as harvesters and seeders

Aerospace: In some cases where lightweight and high-precision requirements are needed, special materials or designed synchronous belts may be used

Electronic equipment manufacturing: used for precise position control and motion transmission on precision instruments and production lines

Fitness equipment such as treadmills and spinning bikes also use synchronous belts in their transmission systems