+86-19862000127

+86-19862000127

In the world of lifting and rigging, "Mounted Pulley" systems play a crucial role. According to a recent report by the Rigging Institute, over 75% of lifting operations use these systems for improved efficiency. Mounted Pulleys help reduce friction and increase mechanical advantage, making them essential in various industrial applications.

Expert Johnathan Hayes, a senior engineer at LiftTech Solutions, once stated, "Understanding the nuances of mounted pulleys can transform your lifting strategies." This highlights the importance of mastering proper techniques for optimal performance.

However, not all users fully grasp their capabilities. Many overlook maintenance, which can lead to failures. The right information is vital. Effective use of Mounted Pulleys demands knowledge and experience. Embracing continuous learning and adapting strategies are essential for success in this field. Overconfidence can lead to mistakes; it’s important to reflect on practices regularly.

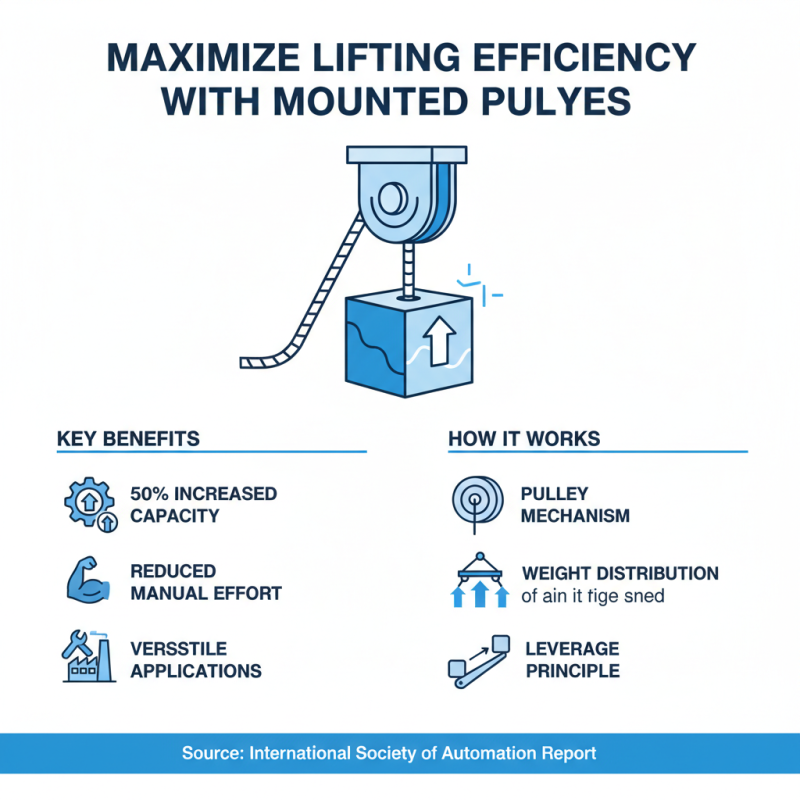

Mounted pulleys are essential tools in various lifting applications. They consist of a wheel on an axle, enabling efficient weight distribution and movement. By using a fixed anchor point, they simplify the lifting process. The mechanics are straightforward yet effective. A rope or cable passes over the wheel, allowing for smooth lifting with reduced friction.

Understanding the basic setup is crucial. Pulleys can be stationary or movable. Stationary pulleys change the direction of force. They make lifting easier, but require the same amount of input force. Movable pulleys lessen the load, requiring less effort. This duality creates opportunities for efficiency, but also complexity. The balance between force and mechanical advantage is delicate.

While mounted pulleys are practical, their usage demands careful planning. Miscalculating the load or angles can lead to accidents. A poorly installed pulley might not achieve the intended efficiency. Reflecting on past mistakes is part of the learning journey. Adjustments are sometimes necessary to improve performance. Embracing these challenges could enhance your lifting techniques significantly.

In mounted pulley systems, lifting efficiency hinges on several key factors. Proper alignment is crucial. When pulleys are misaligned, friction increases. This friction drains energy. It's essential to check that each component is correctly positioned. Remember, even a slight misalignment can lead to significant losses in lifting power.

The choice of rope material also impacts efficiency. Lighter, durable ropes can glide more easily. If the rope is too heavy, it can cause unnecessary drag. Additionally, the diameter of the rope must match the pulley size. An incorrect match can lead to wear and tear, reducing lifespan. These details matter more than one might think.

Another aspect to consider is the load distribution. Uneven loads can create imbalance. This not only complicates lifting but may also risk damage to the apparatus. It’s vital to assess weight distribution before each lift. Reflecting on these elements can reveal areas for improvement. Efficiency in lifting is often about the small adjustments, which can make all the difference.

Setting up mounted pulleys correctly is crucial for effective lifting. Choose a sturdy anchor point. Ensure it can handle the load and stress. The height of the pulley also matters. It should be positioned for smooth operation. Consider the angle of the rope. A 90-degree angle between the pulley and the load is ideal. However, many users overlook this detail and face complications.

Maintaining a tidy setup is vital. Loose ropes can tangle and create friction. Regularly inspect for wear and tear. A frayed rope can lead to accidents. It’s good practice to have backup equipment. Relying on a single pulley system can be risky. Think about the load type, too. Heavy, irregularly shaped loads may require additional safety measures. Ignoring these factors can lead to inefficiencies.

Testing the system before actual use is essential. Sometimes, there are unexpected issues. Pulleys can squeak or bind, affecting performance. It’s important to reflect on past setups to avoid repeating mistakes. Document any adjustments made. Learning from each experience improves future efficiency and safety.

When using mounted pulleys for lifting tasks, common mistakes can hinder efficiency. One frequent error is loading unevenly. Distributing weight unevenly can cause the pulley system to be unstable. This instability may lead to accidents or equipment damage. Always check the load before lifting.

Another mistake is neglecting maintenance. Pulleys need regular inspections to function properly. Rust, dust, and wear can compromise their performance. Ensure that all parts are clean and lubricated. Address any signs of wear immediately to avoid further issues.

Proper technique is also crucial. Many users pull the rope too quickly, which can decrease control. Take your time. Apply steady pressure while lifting. This approach allows for better control and reduces the risk of errors. Remember that efficiency comes from careful handling, not just speed. By avoiding these mistakes, you can enhance your lifting techniques significantly.

| Lifting Technique | Common Mistake | Efficiency Impact | Tip to Avoid Mistake |

|---|---|---|---|

| Single Pulley Lift | Incorrect pulley placement | Reduced lifting power | Ensure proper alignment |

| Block and Tackle | Overloading the system | Increased risk of failure | Follow weight limits |

| Multi-Pulley Setup | Ignoring friction | Inefficient lifting | Lubricate pulleys regularly |

| Directional Pulley System | Wrong direction of pull | Loss of control | Check direction before lifting |

| Vertical Lift System | Rushing the setup | Compromised safety | Take time to secure setup |

Mounted pulleys are essential tools for maximizing lifting efficiency. Their design allows for significant weight reduction in lifting tasks. According to a report by the International Society of Automation, utilizing a mounted pulley system can enhance lifting capacity by up to 50%. This improvement can dramatically impact various industries, from construction to manufacturing.

One crucial technique to consider is the angle of the rope. Adjusting the angle can significantly affect the load's distribution. A report from the National Institute of Standards and Technology outlines that even a slight deviation in angle can alter the effective weight being lifted. Users should practice setting up their systems to identify the optimal angle for their specific applications.

Monitoring equipment wear is another essential aspect. Pulleys can degrade over time, affecting performance and safety. Regular inspections can help prevent accidents. A study from the American Society of Mechanical Engineers highlights that 30% of pulley-related accidents result from neglected maintenance. Users must remain vigilant and create checklists to ensure all parts are functioning correctly.