+86-19862000127

+86-19862000127

In the realm of mechanical power transmission, the choice of the right Mxl Belt Pitch is crucial for achieving optimal performance in various applications. Mxl belts are widely recognized for their efficiency, durability, and versatility, making them a popular choice among engineers and designers. However, not all Mxl Belt Pitch options are created equal, and selecting the most suitable one can significantly impact the efficiency, lifespan, and overall functionality of a system.

This article explores the top five Mxl Belt Pitch options, delving into their unique characteristics and advantages. By understanding the nuances of each option, users can make informed decisions that enhance performance while minimizing wear and tear. Whether for high-speed conveyors, robotics, or other mechanical systems, the right Mxl Belt Pitch can lead to remarkable improvements in motion transfer and energy efficiency. In the following sections, we will outline the features of these top choices, equipping you with the knowledge to choose the best fit for your specific needs.

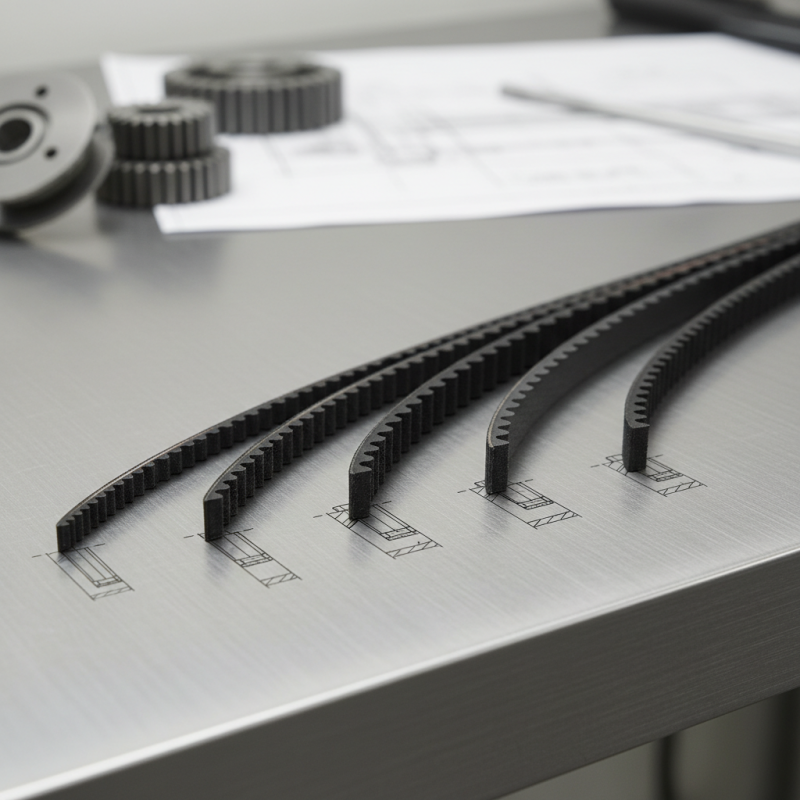

Understanding MXL belt pitch is crucial for achieving optimal performance in applications where precise motion transfer is required. MXL belts are designed with a pitch of 0.2 inches, which refers to the distance between the centers of two consecutive teeth on the belt. This specific measurement is important because it determines the spacing between teeth on both the belt and the accompanying pulleys. Selecting the right belt pitch can impact the efficiency of a system, as it influences factors such as speed, load capacity, and overall operational reliability.

In performance-driven environments, the MXL belt pitch enables smooth and consistent movements, reducing the risk of slippage and wear. Due to its standardized pitch, MXL belts are often preferred for applications requiring synchronization between multiple components, such as in robotics, conveyor systems, and other automated machinery. Understanding the significance of the MXL belt pitch helps engineers and designers optimize their systems to meet high-performance standards, thereby ensuring longevity and efficiency in operations.

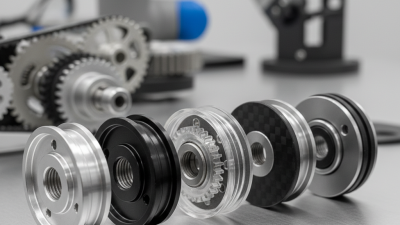

When selecting high-performance MXL belts, there are several key characteristics to consider that can significantly impact the efficiency and reliability of your mechanical systems. First and foremost, the material composition of the belt plays a vital role. High-quality MXL belts are typically made from durable materials such as neoprene or polyurethane, which offer excellent wear resistance, flexibility, and strength. This ensures that the belt can withstand various operational stresses without compromising its functional integrity.

Another important characteristic is the precision of the belt's construction. High-performance MXL belts are manufactured with strict tolerances, ensuring that they maintain their shape and performance under load. This precision minimizes slippage and enhances power transmission, making the system more efficient. Additionally, examining the teeth design is crucial; well-defined teeth facilitate smooth engagement with the pulleys, reducing wear and tear while enhancing overall performance. By focusing on these key features, you can ensure that your MXL belt operates effectively and contributes to the optimal performance of your machinery.

In various industrial applications, selecting the right MXL belt pitch is vital for ensuring optimal performance and durability. MXL belts, with a tooth pitch of 2.032 inches, are commonly used in timing and synchronous transmission due to their efficiency in power transfer. According to a recent industry report, MXL belts can reduce slippage and provide higher speed potential when compared to V-belts, making them an ideal choice for precision machinery and robotic systems.

When considering MXL belt options, it is crucial to evaluate the specific requirements of your operation. For high-torque applications, reinforced MXL belts that feature advanced materials can effectively handle increased loads while minimizing wear and tear. Furthermore, utilizing adjustable pitch pulleys can enhance the performance of MXL belt systems by allowing for fine-tuning and adjustments based on operational demands.

Tips: Regular maintenance checks of MXL belt systems are essential. Inspecting for wear, proper tension, and alignment can prolong the lifespan of the belts and prevent costly breakdowns. Additionally, ensuring proper lubrication in systems that require it can significantly enhance the efficiency of power transmission, keeping machinery running smoothly and effectively.

This chart represents the performance metrics of the top five MXL belt pitch options across different applications. The values indicate the efficiency rating based on load capacity, speed, and wear resistance.

When selecting the ideal MXL belt pitch options for your application, several factors must be considered to ensure optimal performance. One of the most critical aspects is the load capacity and the specific requirements of the machinery involved. The MXL pitch is well-suited for lighter loads, making it a popular choice in applications where space is limited and weight constraints are a priority. Understanding the operational conditions, such as speed and torque, can significantly affect the performance of the belt in a given system.

Another essential factor is the environmental conditions in which the belt will operate. Factors such as temperature, humidity, and exposure to chemicals can impact the longevity and efficiency of the belt. Selecting materials that can withstand these conditions will not only enhance performance but also reduce maintenance needs. Additionally, alignment and tensioning are crucial considerations; improper tension can lead to premature wear or failure, whereas accurate alignment ensures smooth operation. By carefully evaluating these factors, users can make informed decisions on MXL belt choices, ultimately contributing to improved system reliability and efficiency.

| Belt Type | Pitch (inches) | Material | Max Load (lbs) | Typical Application |

|---|---|---|---|---|

| MXL Standard | 0.08 | Polyurethane | 50 | Small machines, 3D printers |

| MXL Tooth Profile | 0.08 | Nylon | 70 | Robotics, conveyor systems |

| MXL High Flex | 0.08 | Rubber | 60 | Dynamic applications, packaging |

| MXL Steel Reinforced | 0.08 | Polyurethane | 80 | Heavy machinery, automotive |

| MXL Antistatic | 0.08 | Polyurethane | 65 | Electronics, clean rooms |

Maintaining the performance and longevity of MXL belts is crucial for optimal efficiency in mechanical applications. Regular maintenance can significantly extend the lifespan of these belts, which, according to industry reports, can last up to 50% longer when proper upkeep is practiced. A well-maintained MXL belt not only operates more efficiently but also reduces the risk of unexpected breakdowns, ultimately saving costs and downtime in production.

One essential tip for maintaining MXL belts is to regularly inspect them for signs of wear, such as fraying or cracking. Additionally, ensuring proper tension is crucial; belts that are too loose can slip, while overly tight belts can cause undue stress, leading to premature failure. A study by the Mechanical Power Transmission Association indicates that maintaining correct tension can increase belt life significantly, with optimal operating conditions yielding up to a 30% improvement in performance.

Another effective maintenance strategy involves regular cleaning of the belt and pulley system. Contaminants like dust and grease can accumulate, affecting the belt's grip and efficiency. Implementing a routine cleaning schedule ensures that these components remain free of debris, allowing the belt to operate smoothly. Furthermore, lubricating the bearings and other moving parts can also enhance the overall system performance, yielding beneficial impacts on efficiency and reducing friction-related wear.