+86-19862000127

+86-19862000127

In the realm of mechanical engineering, the tapered pulley plays a crucial role. This component is vital in various applications, from conveyor systems to automotive transmissions. Richard Smith, a renowned expert in pulley design, once remarked, "The efficiency of a tapered pulley can define the success of a machine." His words highlight the significance of this simple yet sophisticated device.

A tapered pulley features a conical shape that allows for variable speed control. As the belt runs along its surface, the narrower end can increase the speed, while the wider end slows it down. This unique design offers flexibility in different operational settings. However, not all tapered pulleys are created equal. Inadequate materials or misalignment can lead to performance issues.

Understanding the mechanics of a tapered pulley is essential for optimizing machine performance. Observations show that even small variations in installation can affect efficiency. Engineers must be mindful of these factors to prevent costly mistakes. The nuanced nature of tapered pulleys serves as a reminder that precision and attention to detail are paramount in engineering.

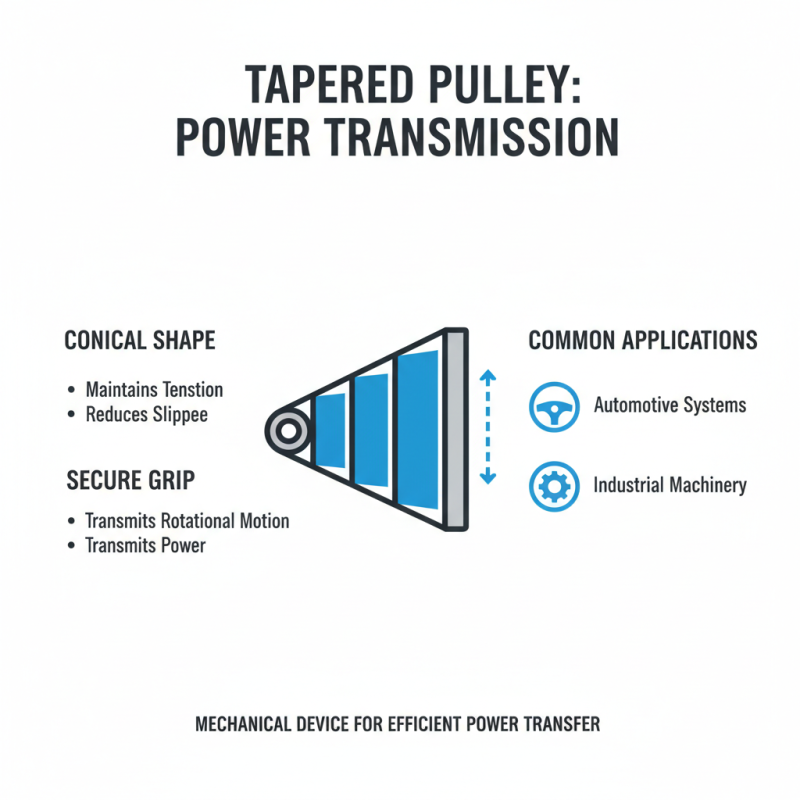

A tapered pulley is a type of mechanical device used to transmit rotational motion and power. Its design features a conical shape that allows belts or ropes to grip securely. This unique shape helps maintain tension while reducing slippage. Tapered pulleys are commonly found in various applications, from automotive systems to industrial machinery.

When using a tapered pulley, it is essential to ensure proper alignment. Misalignment can lead to increased wear on belts and components. Additionally, always inspect for wear and tear. Regular maintenance can prevent unexpected failures. A general rule: if you notice unusual noise, check it out.

Tips for using a tapered pulley: First, always follow the manufacturer's specifications for installation. Correct specifications ensure optimal performance. Pay attention to the pulley material. Some materials perform better under specific conditions. Lastly, remember that a well-maintained pulley system improves efficiency. Keep an eye on tension levels and adjust as necessary. Tapered pulleys are simple yet vital components. Their effectiveness relies on user understanding and care.

Tapered pulleys are unique components in mechanical systems. They function based on a simple yet effective principle. The pulley’s design allows for variable speed and torque transfer. As the belt moves along the taper, the diameter adjusts. This affects the speed at which the belt operates. A smaller diameter means higher speed, while a larger diameter provides more torque.

When using tapered pulleys, precision is key. Any misalignment can cause significant inefficiencies. Ensure that the alignment is correct when installing. This can save wear on the belt and extend its life. Regular maintenance is also crucial. Check for signs of wear or damage frequently.

Tip: Always clean the pulleys and belts regularly. Dust and debris can impact performance. This simple task can prevent larger issues down the line. Additionally, consider your load requirements. Overloading a tapered pulley will lead to premature failure. Be mindful of how these components interact within your system. Reflect on your usage to make improvements where needed.

| Feature | Description |

|---|---|

| Design | Tapered pulleys have a conical shape that allows for adjustable belt tension. |

| Functionality | They enable the transmission of motion and power by varying the diameter where the belt rides. |

| Applications | Commonly used in vehicles, conveyor systems, and heavy machinery. |

| Advantages | Improved grip and reduced slippage; allows for easy adjustment of speed and torque. |

| Maintenance | Regular inspection for wear and alignment is important for optimal performance. |

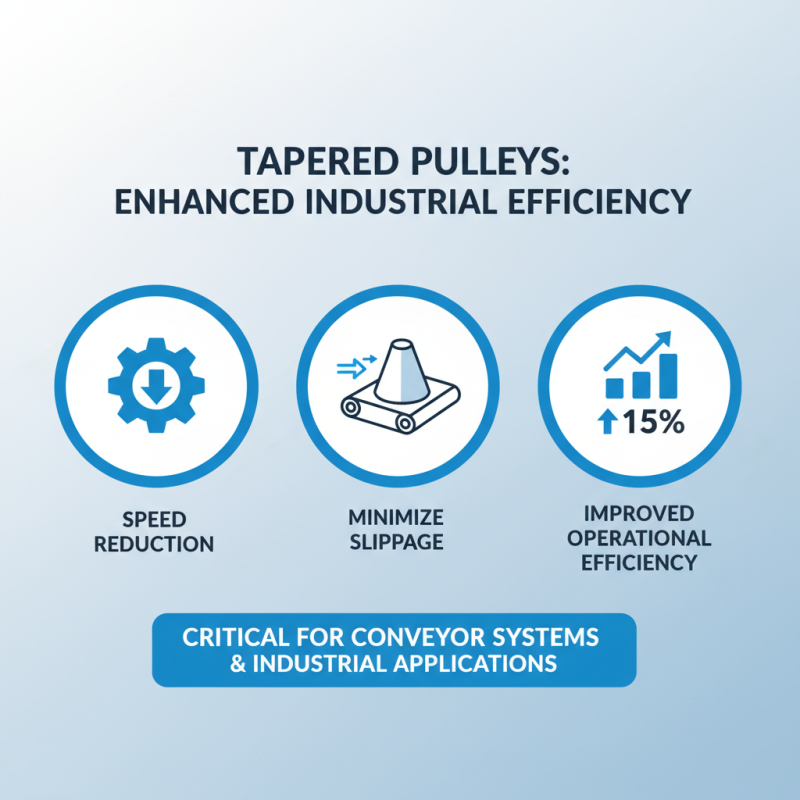

Tapered pulleys play a critical role in various industrial applications. They are designed to support belts in systems where speed reduction is essential. In many conveyor systems, tapered pulleys help minimize slippage and improve overall efficiency. Research indicates that using tapered pulleys can enhance operational efficiency by up to 15% compared to traditional pulleys.

In manufacturing, these pulleys are vital in machines that require variable speed adjustments. For instance, in textile factories, they are used to optimize the movement of materials through different processing stages. The precision of a tapered pulley allows for smooth transitions between belt speeds, which is crucial in preventing material damage. However, improper alignment can lead to increased wear and tear, ultimately affecting production output.

The automotive industry also benefits from tapered pulleys. They assist in adjusting engine components to maximize power delivery. A study found that using these pulleys can improve fuel efficiency by about 10% in specific engine designs. Still, manufacturers often overlook regular maintenance checks, which can result in decreased performance over time. Balancing efficiency with maintenance is a challenge that many industries face.

Tapered pulleys have distinct pros and cons. One advantage is improved grip. The tapered design allows the belt to fit snugly. This enhances power transmission. Additionally, they reduce slippage. It’s beneficial in high-tension applications.

On the downside, tapered pulleys may require precise alignment. Misalignments can cause excessive wear. They can be challenging to install correctly. Another issue is the increased production costs. Custom designs are often necessary. This might be unfavorable for some projects.

Tips: Always check alignment during installation. Regular maintenance can prevent issues. If you notice wear, replace the component promptly. It's better to address problems early than later.

Tapered pulleys are vital components in various machines. They help in transferring power efficiently. However, proper maintenance is crucial for their longevity. Neglecting maintenance can lead to excessive wear and malfunction.

Tips for maintaining tapered pulleys include: