+86-19862000127

+86-19862000127

In the realm of mechanical systems, the "Sliding Pulley" has emerged as a vital component across various industries, enhancing efficiency and versatility in applications ranging from construction to engineering. According to a recent industry report by the Mechanical Systems Research Institute, the global market for pulleys, particularly sliding types, is expected to grow at a compound annual growth rate (CAGR) of 6.5% over the next five years, reflecting a significant upturn in demand. This increasing interest underscores the importance of understanding how sliding pulleys function and their impact on project outcomes.

As industry expert Dr. John Reynolds, a leading mechanical engineer, notes, "The sliding pulley system not only optimizes load distribution but also minimizes friction, thereby improving overall productivity." This statement encapsulates the essential role sliding pulleys play in enhancing mechanical advantages in various applications. By allowing for smoother movement and greater control, sliding pulleys are transforming project designs and execution strategies. As we delve deeper into the workings and applications of sliding pulleys, we will explore how these systems can be effectively implemented to meet the demands of modern engineering challenges.

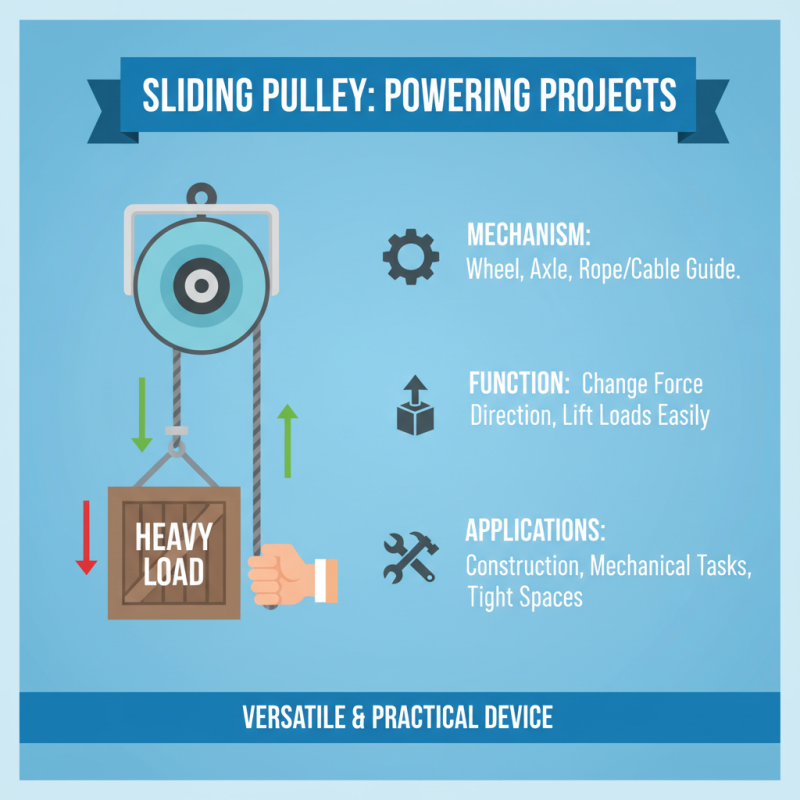

A sliding pulley is a versatile and practical device used in various projects, particularly in construction and mechanical applications. Essentially, it consists of a wheel that rotates around an axle and is designed to guide a rope or cable. This simple yet effective mechanism allows for the easier movement of loads by changing the direction of the force applied. When pulling down on one side of the rope, the pulley allows the load on the other side to be lifted with less effort, making it an essential tool for lifting heavy objects or for applications where space is constrained.

The design of a sliding pulley often incorporates a frame that allows the pulley to move along a track, providing additional flexibility in how loads are managed. As the pulley slides, it can accommodate varying angles of pull and adjust to different heights easily. This functionality is particularly useful in overhead lifting systems, rigging, or any project where mobility and efficiency are critical. Utilizing a sliding pulley not only enhances the mechanical advantage but also contributes to safer and more effective handling of materials, whether in a workshop or on a construction site.

A sliding pulley is a simple yet effective mechanical device that plays a crucial role in various projects, particularly in lifting and lowering loads. Its design is based on a wheel that freely rotates around an axle, which enables the rope or cable to slide smoothly across the wheel. This mechanism significantly reduces the friction that would normally occur if the rope were pulled over a fixed surface, allowing for easier movement and control of the load. Understanding the basic mechanics of sliding pulleys can enhance the efficiency and safety of various applications, from construction to theatrical rigging.

The operation of a sliding pulley relies on the principles of leverage and mechanical advantage. When a load is attached to one end of the rope, pulling the other end generates a force that is distributed across the pulley system. Each added pulley changes the direction of the force applied, making it easier to lift heavier objects. For instance, using a combination of fixed and movable pulleys allows you to lift a load with less effort compared to lifting it directly. By mastering the functions of sliding pulleys, users can design systems that are not only efficient but also adaptable to different challenges, ensuring success in their projects.

Sliding pulleys are versatile tools that find applications across a variety of projects, making them invaluable in many fields, from construction to outdoor activities. One of the most common uses of sliding pulleys is in the rigging of heavy materials. In construction sites, they assist in lifting and relocating loads efficiently, minimizing labor costs and reducing the risk of injury. By utilizing a sliding pulley system, a single worker can manage heavy equipment and building materials with ease, significantly enhancing productivity.

In addition to construction, sliding pulleys are integral in recreational applications. They are often employed in outdoor sports like climbing and zip-lining, where they help create smooth, controlled movements along a cable. By allowing climbers to use less energy when ascending or traversing, sliding pulleys improve safety and performance. Furthermore, these pulleys can be adapted for use in home projects, such as DIY hoists or garden trellises, making them accessible tools for hobbyists looking to tackle various tasks more effectively. The adaptability of sliding pulleys across different projects highlights their importance in both professional and personal undertakings.

Sliding pulleys are essential components in various mechanical systems, providing unique advantages that enhance efficiency and ease of operation. One of the primary benefits of using sliding pulleys is their ability to reduce friction and wear in a system. Unlike fixed pulleys, sliding pulleys can move along a track or support, which allows them to adjust to the changing angles of force application. This adaptability minimizes resistance, thereby improving the overall performance and extending the lifespan of the system.

Additionally, sliding pulleys contribute to better load distribution. By enabling the user to change the direction of force application easily, sliding pulleys help to evenly distribute loads across the mechanical system. This feature is particularly beneficial in applications that involve heavy lifting or dynamic movements. Moreover, sliding pulleys can be integrated into various setups to enhance mechanical advantage, making complex tasks like lifting and hoisting more manageable. Their design encourages versatility, allowing engineers and hobbyists alike to incorporate them into diverse projects effectively.

Proper installation and maintenance of a sliding pulley are essential for ensuring optimal performance and longevity. To install a sliding pulley, begin by selecting a sturdy mounting surface that can support the weight of the pulley and the load it will carry. Ensure that the pulley is aligned properly, as incorrect alignment can lead to increased friction and premature wear. Use high-quality fasteners to secure the pulley in place, and double-check that it is firmly anchored before attaching any load. For safety, make sure to follow all applicable guidelines and recommendations for weight limits and installation practices.

Maintaining a sliding pulley involves regular inspections and lubrication. Check the pulley for signs of wear, such as cracks or deformation, and replace any damaged components promptly. Ensure that the rope or cable runs smoothly over the pulley without any snags or obstructions. Apply a suitable lubricant to the pulley bearings periodically, which helps reduce friction and prolongs the lifespan of the component. Keeping the sliding pulley clean and free from debris will also contribute to its efficiency and reliability, making your projects run more smoothly.

| Feature | Description | Installation Tips | Maintenance Tips |

|---|---|---|---|

| Material | Typically made from durable metals or reinforced plastics. | Ensure the surface is clean and free from dust before installation. | Check for wear and lubricate periodically. |

| Load Capacity | Varies based on design; can handle weights from small tools to heavy loads. | Always verify load specifications before use. | Avoid exceeding the recommended load limit to prevent damage. |

| Types | Includes fixed, movable, and combination pulleys. | Select the type that best fits your project's needs. | Inspect the pulley for any signs of damage before usage. |

| Applications | Used in construction, sailing, and lifting heavy objects. | Refer to load charts and application guidelines. | Clean and inspect regularly to extend tool life. |