+86-19862000127

+86-19862000127

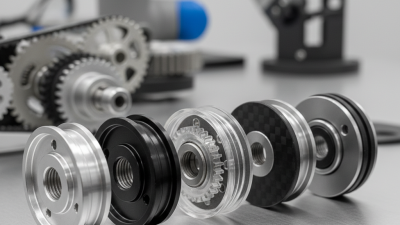

Choosing the right T5 Belt Pulley is a critical step in ensuring the efficiency and reliability of your mechanical project. A T5 Belt Pulley, with its specific design for T5 belts, plays a pivotal role in power transmission, allowing for smooth operation and adequate torque handling. Given the various options available in the market, selecting the correct pulley can significantly influence the overall performance of your mechanical system.

When considering a T5 Belt Pulley, it is essential to factor in various criteria such as material, size, and load capacity. The material of the pulley affects its durability and suitability for specific applications, while the size determines compatibility with other components of the drive system. Load capacity must also match the demands of your project to prevent premature failure. Understanding these elements will enable you to make an informed choice that aligns with your project's requirements and operational goals.

This guide serves to equip you with the necessary knowledge and insights to navigate the selection process of T5 Belt Pulleys, ensuring that you can optimize your mechanical project efficiently and effectively. Whether you are a seasoned engineer or a DIY enthusiast, making the right choice will contribute to the longevity and success of your endeavors.

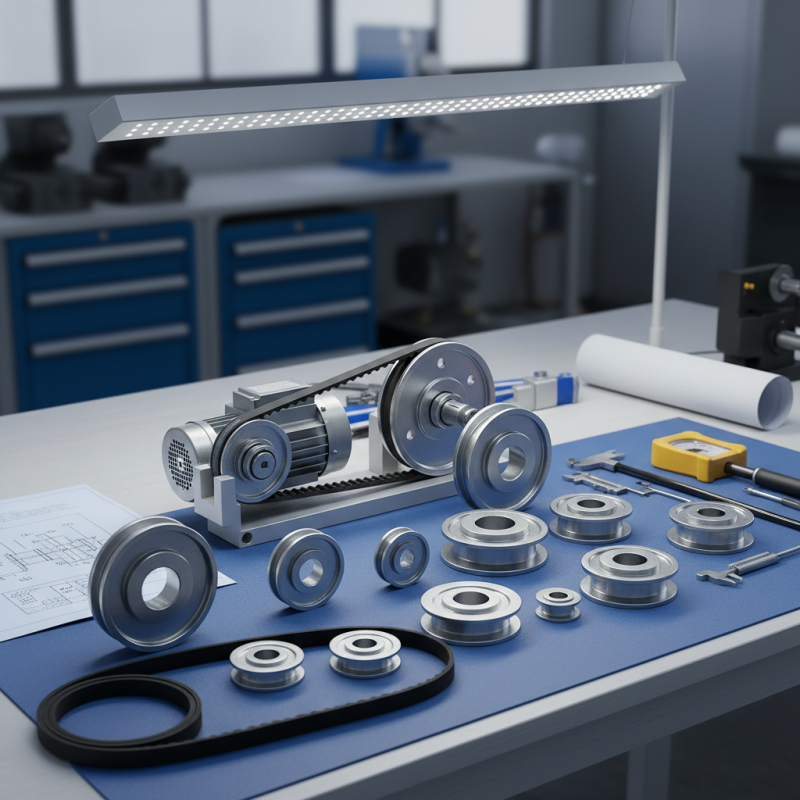

When selecting the right T5 belt pulley for your mechanical project, it is essential to first understand the basic types available in the market. T5 belt pulleys are commonly categorized into two main types: fixed and adjustable. Fixed pulleys have a set diameter that determines the speed ratio and torque transmission between the motor and the driven equipment. They are typically used in applications where consistent speed and efficiency are paramount, making them a preferred choice for conveyor systems and fans. On the other hand, adjustable pulleys allow for variations in diameter, enabling users to change the speed and torque characteristics on the fly, which can be beneficial for projects requiring flexibility.

According to a recent industry report by Grand View Research, the global industrial pulleys market is projected to reach $3.2 billion by 2025, driven largely by advancements in manufacturing and automation technologies. Additionally, the report highlights that T5 belt systems are favored in the mechanical sector for their efficiency, with power losses often reduced to as low as 1.5% compared to traditional V-belts. Understanding these fundamental pully types and their strengths can help engineers and project managers make informed decisions that enhance operational efficiency and meet specific project requirements.

Choosing the right T5 belt pulley for your mechanical project can significantly influence the efficiency and performance of your system. When selecting a T5 belt pulley, one of the key factors to consider is the pulley diameter. According to industry standards, a larger pulley diameter can reduce the belt speed, resulting in lower friction and wear. However, it’s crucial to balance this with the required torque and speed for your specific application. A study by the American National Standards Institute highlights that incorrect pulley sizing can lead to energy losses of up to 10% in mechanical systems.

Another critical factor is the material of the pulley. Materials such as aluminum, steel, and plastic each have their unique advantages and disadvantages. For high-load applications, metal pulleys tend to offer superior strength and durability, making them a preferred choice in many industries. Conversely, for lighter applications, polymer pulleys may provide adequate performance while reducing overall weight. The Mechanical Engineering Report indicates that a substantial portion of mechanical failures is often traced back to material selection; therefore, understanding the operational environment and load requirements is essential for making the right choice.

**Tip:** Always consult with engineering specifications and performance data when determining the load requirements for your project. Understanding the belt's capacity and the necessary tension can save you from future operational disruptions.

**Tip:** Conducting a proper alignment check between the pulleys can enhance your system's efficiency by minimizing wear on both the belt and the pulleys, ultimately extending their lifespan.

When selecting a T5 belt pulley for your mechanical project, evaluating the material and durability is crucial. T5 pulleys are typically constructed from materials like aluminum, steel, and various plastics. Each material offers unique strength, weight, and cost characteristics. For instance, aluminum is lightweight and resistant to corrosion, making it a preferred choice for applications where reduced weight is critical. On the other hand, steel pulleys provide superior durability and are ideal for high-load applications, even though they may come with increased weight. According to the Society of Automotive Engineers, pulleys made from high-strength materials can withstand up to 30% more load than standard-grade options, ensuring long-term reliability in machinery.

Durability is not just about material strength; it's also influenced by design and manufacturing processes. Precision machining and surface treatments can significantly enhance the performance of T5 pulleys. A study from the American National Standards Institute highlighted that pulleys with enhanced surface finishes show improved resistance to wear and fatigue, thereby extending their service life. When selecting a T5 belt pulley, it’s essential to consider the environmental conditions it will face, such as exposure to moisture or chemicals, which can deteriorate certain materials over time.

**Tips:** Always check the manufacturer's specifications for load ratings and operating conditions. Consider conducting a failure mode analysis to understand potential weaknesses in your pulley selection. Lastly, consult with professionals to ensure that the material choice aligns with the specific demands of your project, optimizing both performance and longevity.

When selecting a T5 belt pulley for your mechanical project, sizing and compatibility play critical roles. To begin with, measuring the shaft diameter is essential, as pulleys must fit securely onto the shaft to ensure effective power transmission. Using a caliper or a micrometer, accurately measure the shaft where the pulley will be installed. This dimension will help you determine the correct bore size needed for the pulley, ensuring a proper fit and reducing the risk of slippage during operation.

Next, consider the overall diameter of the pulley as this influences the speed ratio and torque characteristics of your system. The ideal pulley size depends on the specific requirements of your project, including motor speed and the desired output speed. It is also important to assess the pitch and width of the belt being used. Confirm that the belt matches the pulley specification to ensure compatibility. By carefully measuring these key dimensions and understanding how they interact, you can effectively choose the right T5 belt pulley to meet the unique demands of your mechanical project.

| Parameter | Description | Value |

|---|---|---|

| Belt Width | Width of the T5 belt pulley | 5 mm |

| Pulley Diameter | Overall diameter of the pulley | 50 mm |

| Number of Grooves | Total grooves for the belt | 1 |

| Material | Material of the pulley | Aluminum |

| Compatibility | Compatible T5 belt size | T5 |

| Load Capacity | Maximum load the pulley can handle | 150 N |

| Operating Temperature Range | Temperature range at which pulley functions | -20°C to 80°C |

T5 belt pulleys play a crucial role in various mechanical systems, offering efficient power transmission across different applications. Commonly used in industrial automation, these pulleys are essential in conveyor systems, HVAC units, and machine drives. According to a report by the Power Transmission distributors Association, T5 pulleys effectively handle loads between 1 to 15 HP, making them suitable for medium to heavy-duty applications. Their design allows for smooth operation while minimizing friction and wear, ensuring longevity in demanding environments.

Another significant application of T5 belt pulleys is in robotics and automation systems, where precision and reliability are paramount. The T5 profile, with its five-millimeter pitch, provides improved engagement between the belt and pulley, resulting in higher efficiency during operation. Data from the National Institute of Standards and Technology indicates that using T5 pulleys in robotic systems can enhance energy efficiency by approximately 30% compared to older pulley systems. This efficiency translates into lower operational costs and increases the overall productivity of mechanical projects, underscoring the importance of selecting the right T5 belt pulley based on the specific requirements of the application.