+86-19862000127

+86-19862000127

Choosing the right locking pulley can be challenging. There are various factors to consider. A locking pulley must suit your specific needs.

Think about the load capacity. This is crucial. Too much weight can lead to malfunction. Look for materials that are durable yet lightweight. Quality should never be compromised.

Consider the operating environment too. Is it wet or dry? A locking pulley must withstand its surroundings. Reflection on your actual needs is essential. Too often, users choose based on price alone. This can lead to regrets later. Take your time in making a decision. A well-chosen locking pulley ensures safety and efficiency.

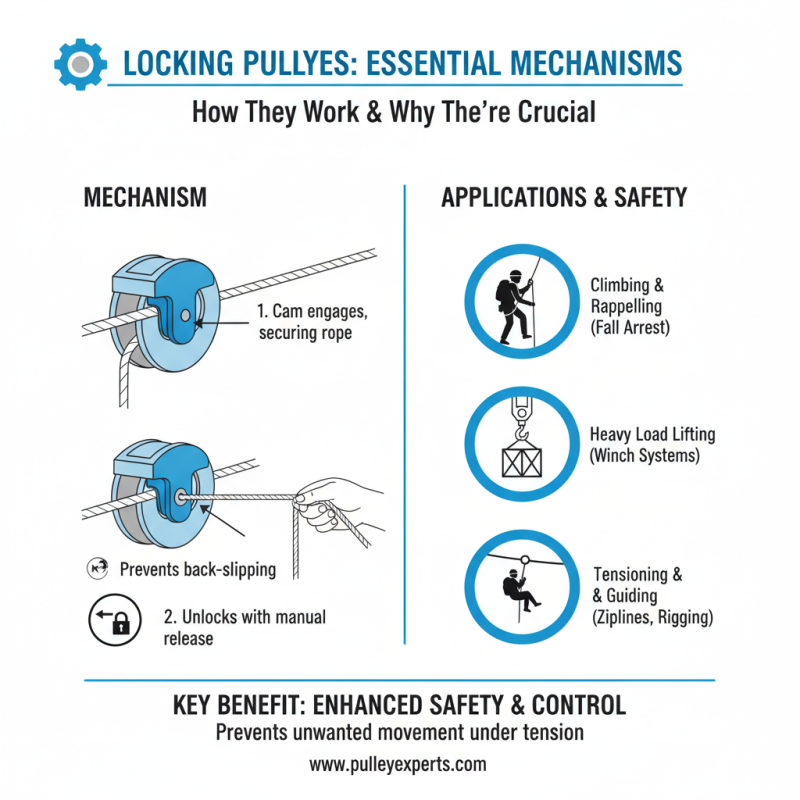

Locking pulleys are essential for various applications, from climbing to lifting heavy loads. Understanding how they work is crucial for selecting the right type. A locking pulley typically has a mechanism that secures the rope in place, preventing unwanted movement. This feature is vital for safety in high-stakes situations.

When choosing a locking pulley, consider its load capacity. This number indicates how much weight it can safely hold. It's easy to underestimate this factor. A pulley with insufficient capacity can lead to serious accidents. Additionally, think about the material used in the pulley. Different materials offer varying durability and weight. While a lightweight option may seem ideal, it might lack the strength you require.

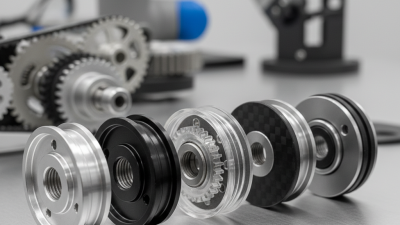

Another aspect to ponder is the pulley size. A larger pulley can handle more rope and reduce friction. However, it may be cumbersome in tight spaces. Finding a balance is not always straightforward. Take the time to assess your specific needs and test out different options. Trial and error can lead to better choices in the long run.

Locking pulleys come in various types, each designed for specific functions. The most common types include single locking, double locking, and automatic locking pulleys. Single locking pulleys are often used for light loads, making them ideal for recreational climbing. Their simplicity allows for quick adjustments in elevation. However, they may not hold heavy loads securely.

Double locking pulleys offer enhanced security by requiring two actions to release. This design is beneficial in situations where load security is critical. According to industry reports, around 70% of climbing incidents are due to pulley failures. Many climbers overlook the critical importance of choosing the right type for their needs.

Automatic locking pulleys are gaining popularity in rescue operations. They engage automatically under load, simplifying use. Yet, they can be more complex and may require training to operate effectively. Misuse can occur if users are unaware of their specific features. Statistics show that improper use leads to increased risk in emergency situations. Understanding these differences ensures safer practices in rigging and climbing activities.

When selecting a locking pulley, several key factors should guide your decision. The working load limit is crucial. It indicates the maximum weight the pulley can safely handle. According to industry reports, a locking pulley with a higher working load limit can significantly reduce the risk of accidents. Always verify this number before purchase.

Another important factor is the material strength. Aluminum pulleys are lightweight and corrosion-resistant. However, steel pulleys provide higher durability. A study from the Rigging Industry Association shows that choosing the right material affects both longevity and performance.

Ease of operation also matters. Some pulleys may require significant effort to engage or disengage the locking mechanism. User feedback often highlights the importance of smooth functionality in often-used systems. If operation feels jerky, it might lead to frustration during use. Assessing user reviews can uncover these subtle issues.

| Feature | Description | Considerations |

|---|---|---|

| Weight Capacity | The maximum load the pulley can handle. | Ensure it exceeds the expected load. |

| Material | The substance from which the pulley is made (e.g., aluminum, steel). | Choose based on durability needs. |

| Pulley Diameter | The diameter affects friction and efficiency. | Larger diameters typically reduce wear. |

| Locking Mechanism | Different types of mechanisms to secure the load. | Consider ease of use and reliability. |

| Sheave Design | Shape and design that affects rope compatibility. | Ensure it's compatible with your ropes or cables. |

| Portability | Weight and size for transport issues. | Lighter pulleys are easier to carry. |

| Cost | The price range for locking pulleys. | Balance quality with your budget. |

Locking pulleys are crucial in many industries, from construction to entertainment. In construction, they help lift heavy materials safely. These pulleys prevent slippage, providing stability in high-pressure situations. For theater productions, locking pulleys assist in managing stage equipment. They keep props suspended correctly and safely throughout performances.

Tips: When selecting a pulley, consider the load capacity. An under-rated pulley can lead to failure. It's important to match the pulley to the specific application. Additionally, think about the environment. Will it be exposed to weather or chemicals? This affects material choice.

In manufacturing, locking pulleys are used in conveyor systems. They ensure consistent movement and reduce wear on machinery. However, flaws in design can lead to inefficiencies. Regular maintenance checks are necessary to ensure smooth operation. Reflecting on the choice of materials and design can save time and resources in long-term applications.

Locking pulleys can significantly enhance your rigging system. Proper maintenance is essential for longevity and performance. Regular checks on the pulley’s locking mechanism can prevent malfunctions. A jammed mechanism can lead to serious issues. Look for signs of wear and tear. If you notice unusual sounds, it might be time for a thorough inspection.

Keep the pulleys clean. Dirt and debris can hinder their functionality. Use a soft cloth to wipe down the pulleys after use. Lubrication is also crucial but should be done carefully. Too much grease can attract dirt. Apply just enough to keep the mechanism smooth. Inspect the bearings regularly. Even a small flaw can affect performance.

Be mindful of storage. Extreme temperatures can compromise a pulley’s integrity. Store them in a cool, dry place. Consider a protective cover to shield them from dust. A little effort in maintenance goes a long way. Sometimes, overlooking small details can lead to bigger problems later. Regular attention will ensure your locking pulleys work effectively when needed.