+86-19862000127

+86-19862000127

When it comes to selecting a 5mm GT2 pulley for your project, the right choice can make a significant difference. Tim Carter, an industry expert and mechanical engineer, once said, "Choosing the right component is key to the success of your design." His words resonate in the world of robotics and automation.

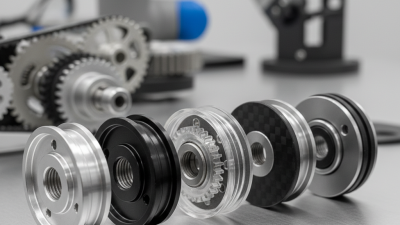

A 5mm GT2 pulley may seem simple, but there are many factors to consider. You need to evaluate material, tooth profile, and compatibility with your system. Often, users overlook these details, leading to performance issues. A pulley that is too small can slip, while one that is too large may rubber band.

Understanding these nuances is essential for effective engineering. Many projects fail because of poor component selection. Sometimes, even minor adjustments in size can lead to major improvements. Taking the time to analyze your specific requirements ensures that your project runs smoothly and efficiently.

When selecting a 5mm GT2 pulley for your project, understanding specifications is key. The GT2 pulley has a tooth profile designed specifically for timing belts. Its teeth are spaced at 2mm intervals, making it suitable for precise applications. You’ll often find these pulleys in 3D printers and CNC machines, where accuracy is critical.

Consider the material of the pulley. Common options include nylon, aluminum, and plastic. Nylon is lightweight and offers good wear resistance, while aluminum is durable and can handle higher loads. However, plastic options can be cost-effective for lighter applications. Your choice should match the demands of your project.

**Tips:** Always check the weight capacity when choosing a pulley. Overloading can lead to premature wear. Take note of the shaft diameter as well. A mismatch may cause slippage, affecting performance. Sometimes, despite careful choice, issues arise. It’s essential to monitor your setup regularly for any signs of wear or misalignment.

| Pulley Type | Number of Teeth | Material | Weight (g) | Inner Diameter (mm) | Price ($) |

|---|---|---|---|---|---|

| Standard GT2 Pulley | 20 | Aluminum | 15 | 5 | 2.50 |

| Lightweight GT2 Pulley | 16 | Plastic | 10 | 5 | 1.80 |

| Heavy Duty GT2 Pulley | 30 | Steel | 30 | 5 | 4.00 |

| GT2 Pulley with Hub | 24 | Aluminum | 20 | 5 | 3.10 |

| Precision GT2 Pulley | 18 | Plastic | 12 | 5 | 2.00 |

When selecting a 5mm GT2 pulley, material choice is critical. Common materials include plastic and aluminum. Plastic pulleys are lightweight and affordable, making them suitable for low-load applications. However, they wear out quickly. They may crack under high stress. Aluminum options provide greater durability. They handle heavier loads and resist wear better.

Durability is equally important. Consider the operating environment. If your project involves moisture or dust, corrosion-resistant materials are essential. Some pulleys come with protective coatings. This feature can enhance longevity significantly. But remember, coatings may chip or wear off over time. Without proper testing, you may end up with reduced performance.

You should also evaluate the manufacturing quality. Look for smooth surfaces and precise dimensions. Imperfections can lead to vibrations during operation. This, in turn, affects your entire setup. Always weigh your options. It’s essential to reflect on your project’s specific needs. Balancing cost and performance requires careful thought. Each choice has its benefits and drawbacks.

When selecting a 5mm GT2 pulley, assessing load capacity is critical. Many projects require precise torque specifications. According to a report by the International Journal of Mechanical Engineering, a GT2 pulley with a 5mm pitch can generally handle loads ranging from 5 kg to 50 kg. This versatility makes it suitable for various applications, including robotics and CNC machines.

Performance metrics should not be overlooked. The efficiency of a GT2 pulley can significantly influence project outcomes. Data suggests that a high-quality pulley system can achieve 95% efficiency. However, friction and material degradation can reduce this value over time. Users often fail to consider the long-term wear and tear on pulleys. Regular maintenance of the pulley system is essential to maintain optimal performance.

Moreover, environmental factors play a role in the pulley’s performance. Temperature fluctuations and humidity can impact material integrity. Research indicates that maintaining an appropriate operating range can extend the lifespan of GT2 pulleys. Testing in real-life conditions often reveals shortcomings not seen in initial assessments. Users should reassess their selections periodically for better results.

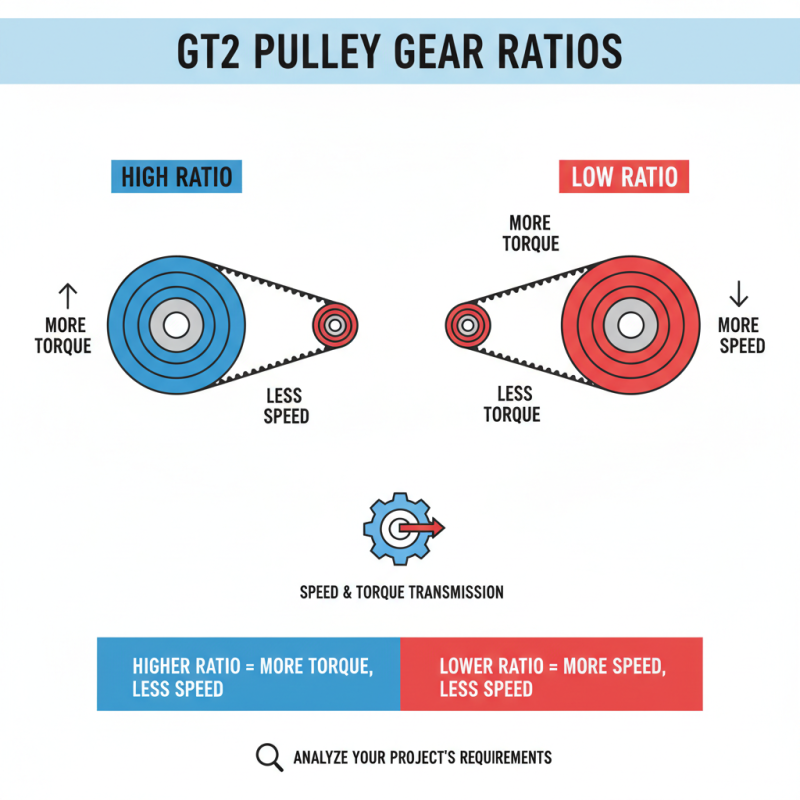

When selecting the right GT2 pulley, gear ratios play a crucial role in your application. Gear ratios determine how speed and torque are transmitted in a mechanical system. A higher ratio means more torque but less speed. Conversely, a lower ratio increases speed with less torque. It's vital to analyze your project's requirements carefully.

One tip to assist in your selection is to consider the motor specifications you are using. Ensure that the pulley can handle the motor's maximum RPM without causing damage. If the chosen pulley is too small, it may lead to overheating or failure. Similarly, pulling too much torque can create unnecessary stress.

It's also wise to account for the material and construction of the pulley. A strong material will withstand wear over time. However, a heavier pulley might slow down your system. Achieving the right balance can be challenging. In some cases, you may need to re-evaluate your choices after testing. Don’t hesitate to switch pulleys if you face performance issues. This process requires reflection and adjustment, but it can lead to optimal results in your project.

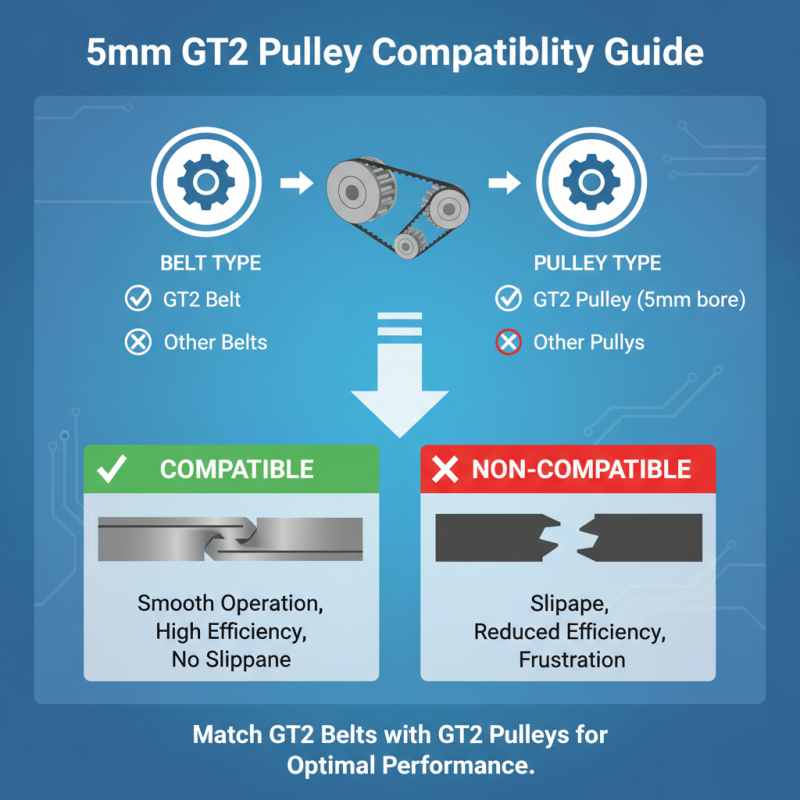

When selecting a 5mm GT2 pulley, compatibility is vital. Your chosen pulley must align with the belts and components in your system. Pay attention to the tooth profile. For GT2 belts, a GT2 pulley ensures smooth operation. Mismatched profiles can lead to slippage and reduced efficiency, causing frustration.

Consider the material of the pulley as well. Aluminum is popular for its strength and durability, but plastic options can be lighter and more cost-effective. However, plastic may wear out more quickly. This compromise between weight and longevity can be perplexing. Ensure your project needs align with these characteristics. The diameter of the pulley also affects speed and torque. Larger diameters may offer higher speeds but less torque, which could complicate designs.

Additionally, assess how the pulley fits with other components. Sprockets, gears, and motors all need to work together without friction. Incorrect sizing might lead to misalignments, requiring more adjustments and testing. Each of these factors contributes to the overall success of a project. Reflect on your choices, as even small errors can derail progress.