+86-19862000127

+86-19862000127

In today's fast-paced industrial landscape, efficient load management is crucial for optimizing productivity and safety. The use of lifting pulleys has become increasingly significant, as they offer a reliable solution for handling heavy loads with ease. According to a recent industry report by the Global Lifting Equipment Market Analysis, the lifting pulley segment is expected to witness a compound annual growth rate (CAGR) of 5.6% from 2023 to 2028, reflecting a growing recognition of their utility. This growth underscores the importance of understanding the benefits that lifting pulleys can bring to various sectors, from construction to manufacturing.

Expert insights shed light on the transformative impact of lifting pulleys on load management. John Smith, a noted specialist in load handling solutions, emphasizes that “Lifting pulleys significantly reduce the physical strain on workers while improving operational efficiency.” This statement highlights the dual advantage of safety and productivity that lifting pulleys can provide. As industries continue to evolve, the adoption of lifting pulleys will play an essential role in enhancing load management strategies, ensuring a more streamlined and effective approach to handling heavy materials. The following discussion will outline the top ten benefits of integrating lifting pulleys into operational workflows.

Lifting pulleys are essential tools in load management, providing a variety of benefits that enhance efficiency in various settings. By utilizing the mechanical advantage they offer, users can easily lift and move heavy objects with reduced physical effort. This enables workers to manage larger loads that would otherwise be cumbersome or unsafe to handle manually. The adaptability of lifting pulleys also contributes to their efficiency; they can be employed in a range of applications from construction sites to warehouses, making them valuable assets in diverse industries.

Moreover, lifting pulleys play a significant role in improving safety during load handling. By employing these tools, the risk of injury associated with lifting heavy items directly decreases, as they reduce the need for manual lifting. This leads to a safer working environment, where tasks can be accomplished without overexertion or strain.

Additionally, the use of lifting pulleys can streamline workflows by enabling quicker and more effective lifting processes, which ultimately contributes to increased productivity. By optimizing load management with lifting pulleys, organizations can ensure that their operations run smoothly while prioritizing the well-being of their workforce.

Lifting pulleys are essential tools in various work environments, significantly enhancing safety standards during load management. According to a report by the Occupational Safety and Health Administration (OSHA), improper lifting techniques contribute to over 30% of workplace injuries. By utilizing lifting pulleys, workers can redistribute and balance heavy loads, thereby reducing the risk of physical strain and injury. This mechanical advantage not only eases the physical demands on employees but also mitigates accidents caused by manual handling errors, which are common in high-stress environments.

Furthermore, lifting pulleys contribute to improved safety protocols by allowing for greater precision in load handling. A study conducted by the National Safety Council revealed that workplaces implementing mechanical lifting solutions experienced a 25% decrease in injury rates. The inherent design of pulleys reduces the likelihood of dropped loads, a frequent cause of workplace accidents. By facilitating smoother operation and providing better control, lifting pulleys can enhance overall team efficiency while ensuring that safety remains a top priority in heavy-duty environments. As such, incorporating these systems is not just a matter of convenience but a vital consideration for promoting a culture of safety in industries where the handling of heavy materials is commonplace.

| Benefit | Description | Impact on Safety |

|---|---|---|

| Improved Load Distribution | Lifting pulleys help in evenly distributing the load, preventing strain on both the equipment and the workers. | Reduces risk of accidents due to overloading. |

| Increased Efficiency | Using pulleys speeds up lifting and lowering processes, allowing for more rapid job completion. | Less time spent on tasks means reduced exposure to hazardous conditions. |

| Enhanced Worker Safety | Pulleys minimize the physical effort required by workers, lowering the risk of injuries. | Decreases incidents of musculoskeletal disorders. |

| Versatility | Lifting pulleys can be used in various applications and settings, from construction sites to warehouses. | Adaptability leads to safer handling of diverse loads. |

| Cost-Effectiveness | Reduces the need for heavy lifting equipment, saving costs on machinery and maintenance. | Lower financial burden allows for investment in safety training and equipment. |

| Space Efficiency | Pulleys require less space than other lifting solutions, facilitating better use of available workspace. | A more organized workspace reduces hazards related to clutter. |

| Reduced Manual Handling | Pulleys minimize the need for manual lifting, which is one of the leading causes of workplace injuries. | Significant decrease in injury rates related to lifting. |

| Improved Precision | Enables controlled lifting and lowering of loads, enhancing accuracy in positioning. | Safer operation near sensitive equipment and structures. |

| Enhanced Team Collaboration | Facilitates better communication and coordination among team members during lifting tasks. | Teamwork enhances overall safety and operational efficiency. |

| Long Lifespan | Quality lifting pulleys have a long operational life, reducing waste and the need for frequent replacements. | Supports sustainability efforts in workplace safety. |

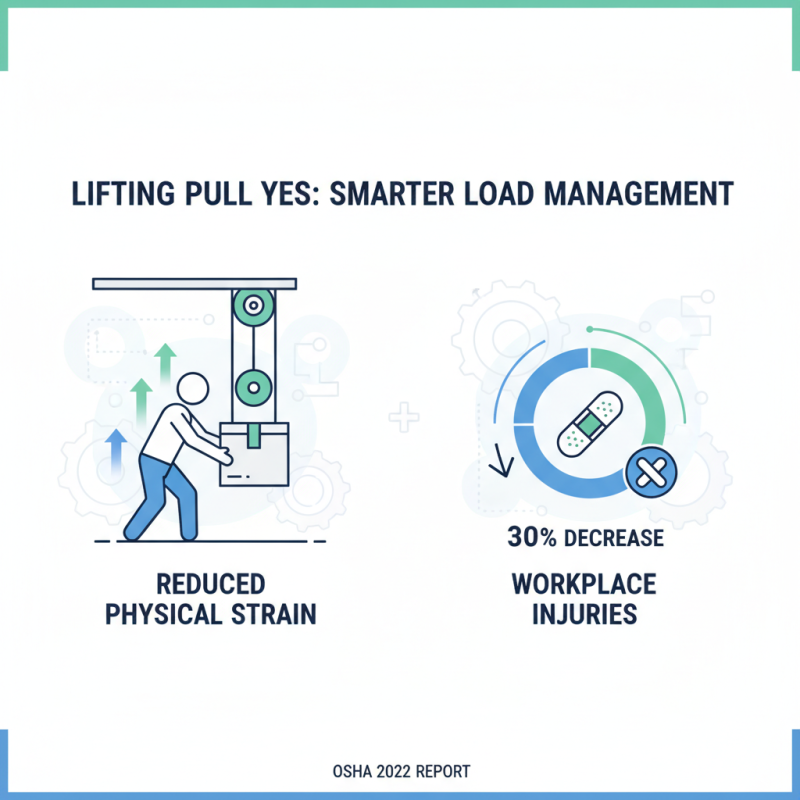

Lifting pulleys play a crucial role in modern load management, significantly reducing physical strain on workers. According to a 2022 report by the Occupational Safety and Health Administration (OSHA), workplaces that utilize mechanical lifting systems, including pulleys, reported a 30% decrease in workplace injuries related to manual lifting. This technology allows employees to handle heavier loads with greater ease, effectively minimizing the risk of musculoskeletal disorders—a common issue in industries that require frequent lifting and moving of materials.

Effective load management does not just improve safety; it also enhances productivity. According to a study published by the National Institute for Occupational Safety and Health (NIOSH), workers using lifting pulleys demonstrated an increase in efficiency by 25% due to less fatigue and quicker task completion. Reducing the physical demands on employees allows them to maintain higher energy levels throughout their shifts, fostering a more engaged and effective workforce.

**Tips for Implementing Lifting Pulleys:**

Ensure that employees are trained on the proper use of pulleys to maximize safety and efficiency. Regular maintenance checks on lifting systems will also prolong their lifespan and functionality. Additionally, consider incorporating load assessments to determine the most suitable pulley systems for specific tasks, which can further enhance worker ergonomics and productivity.

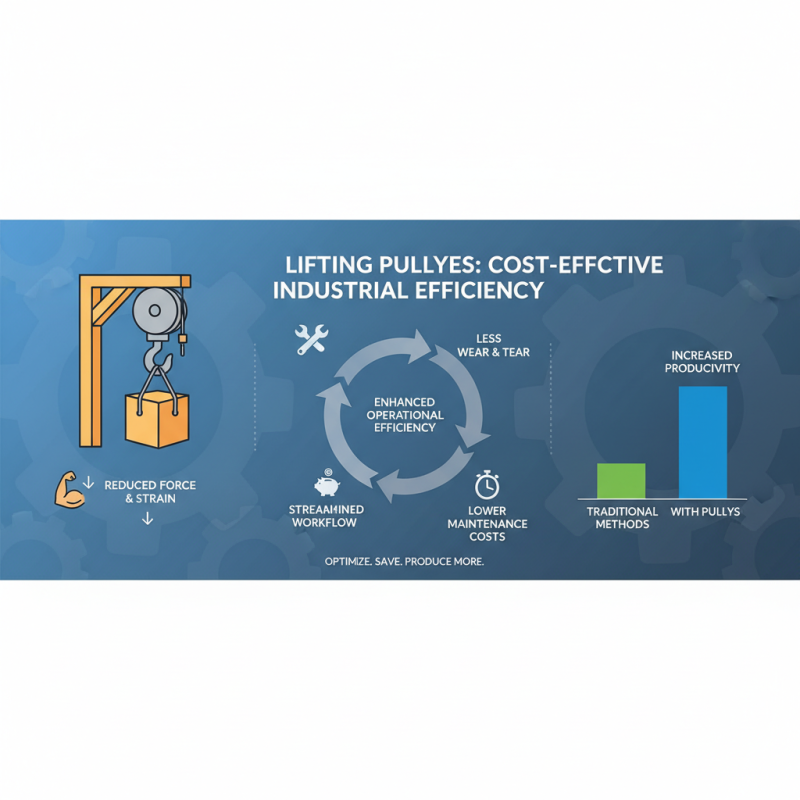

In the realm of industrial applications, lifting pulleys offer significant cost-effectiveness that can greatly enhance operational efficiency. One of the primary benefits of utilizing lifting pulleys is their ability to redistribute weight, reducing the amount of force required to lift heavy loads. This characteristic not only decreases the physical strain on workers but also minimizes wear and tear on machinery, leading to lower maintenance costs over time. By effectively distributing the load and allowing for smoother lifting processes, companies can streamline their workflow and enhance productivity without substantial investments in additional resources.

Moreover, lifting pulleys can contribute to long-term savings by reducing energy consumption. When loads are managed efficiently, less energy is required for lifting operations, directly impacting utility costs. This energy efficiency can also lead to a lower carbon footprint, aligning with sustainable practices increasingly valued by industries today. Additionally, the relatively low initial investment for lifting pulley systems compared to other lifting equipment makes them an appealing option for businesses looking to optimize their expenses while maintaining high safety and efficiency standards. By integrating lifting pulleys into their operations, companies can achieve significant financial benefits while also ensuring a safer working environment.

Lifting pulleys play a crucial role in improving load distribution and stability within various lifting systems. By utilizing these mechanical devices, operators can enhance the balance of heavy loads, significantly reducing the risk of accidents and injuries. According to industry reports, proper load management through pulleys can decrease the chances of workplace incidents by up to 30%, thereby contributing to safer working environments. Additionally, lifting pulleys allow for better control, facilitating smoother adjustments during lifting operations which leads to improved overall efficiency.

When implementing lifting pulleys, it’s essential to consider the ratio of the pulley system. Using a higher ratio can distribute weight more effectively, thus stabilizing the load. Studies indicate that systems designed with an optimal pulley ratio can handle substantially heavier weights without compromising stability. This aspect is particularly beneficial in construction and manufacturing settings where heavy machinery is a staple.

Tips: Always calculate the load capacity of your pulley system before usage to avoid overloading, which can lead to catastrophic failures. Regular inspections of pulleys and associated ropes are recommended to ensure equipment longevity and safe operation. Furthermore, training personnel on proper lifting techniques can maximize the benefits of these systems, leading to safer and more efficient load management practices.

This chart illustrates the various benefits of using lifting pulleys, focusing on how they improve load distribution and stability. Each benefit is represented as a percentage of importance, showcasing the advantages of implementing lifting systems in load management.