+86-19862000127

+86-19862000127

In the realm of mechanical advantages, the Pulley Trolley plays a pivotal role in various applications. Jane Doe, a renowned expert in material handling, states, “The Pulley Trolley revolutionizes our approach to lifting heavy loads.” Her insight highlights its importance in daily tasks.

Pulley Trolleys simplify complex operations. They provide an easy way to lift and move heavy items. In warehouses, these devices reduce strain on workers. Every lift becomes smoother, transforming the work environment. However, improper use can lead to accidents. Understanding proper techniques is crucial for safety.

These devices maintain efficiency in multiple sectors. From construction to home improvement, the Pulley Trolley shines. It’s vital to recognize its limitations. Even the best tools require proper handling. Reflecting on how we utilize them can yield better outcomes.

Pulley trolleys play a significant role in enhancing material handling efficiency across various industries. According to a recent industry report, effective material handling can increase productivity by up to 25%. Utilizing pulley trolleys simplifies the movement of heavy loads. This efficiency not only saves time but also reduces the risk of injuries during lifting tasks. In fact, companies that implement these systems often see a 15% decrease in workplace accidents.

Moreover, pulley trolleys can lead to operational cost savings. Properly designed systems minimize the need for manual handling, which often results in reduced labor costs. A study shows that using mechanical aids can decrease labor costs by as much as 20%. However, it's crucial to assess each workplace requirement. Not every situation may benefit from their use. In some cases, improper application can lead to wasted resources or even increased safety risks.

Flexibility is another key advantage of pulley trolleys. They can be easily adjusted to accommodate various load weights and sizes. This adaptability enables teams to handle diverse tasks efficiently. Yet, without proper training on their use, even the best designs can become ineffective. Workers need to understand how to engage the trolleys safely and effectively, ensuring that the advantages outweigh potential downsides.

| Advantage | Description | Applicability |

|---|---|---|

| Increased Efficiency | Reduces the effort needed to lift heavy loads, leading to faster material movement. | Warehouse, Construction Sites |

| Versatility | Can be used in various applications from industrial to residential settings. | Home Improvement, Factories |

| Reduced Risk of Injury | Minimizes physical strain on workers, lowering the chances of workplace injuries. | Warehouses, Shipping Facilities |

| Cost-Effectiveness | Inexpensive compared to other lifting equipment, offering a high return on investment. | Retail Stores, Workshops |

| Compact Design | Space-saving and easy to store when not in use. | Small Workshops, Home Use |

| Easy Installation | Simple to set up and use without the need for specialized training. | Any setting with need for lifting |

| Durability | Constructed from sturdy materials, providing long-lasting performance. | Industrial Use, Heavy Lifting |

| Enhanced Safety Features | Many models come with safety locks and brakes to secure loads. | Construction, Engineering Projects |

| Customizability | Different models available to suit specific needs and load types. | Manufacturing, Tailored Solutions |

| Improved Workflow | Streamlines lifting and moving processes, enhancing productivity. | Logistics, Import/Export |

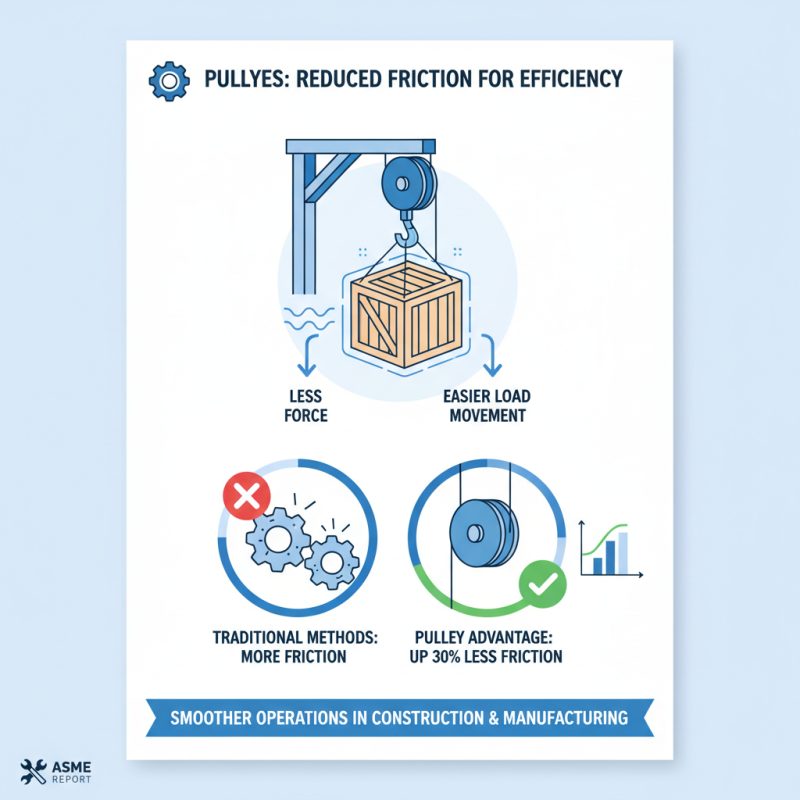

Pulleys are essential tools in various applications, facilitating easier load movement. One of the most significant advantages is reduced friction. This is essential in settings like construction or manufacturing, where efficiency is crucial. A report from the American Society of Mechanical Engineers indicates that using pulleys can reduce friction by up to 30%. This leads to smoother operations.

Enhanced load movement is another benefit. When a trolley system is used, the load can glide with minimal resistance. This improvement in movement is vital in warehouses or shipping. Workers can transport heavy items with ease. Statistics show that load movement efficiency can increase by 50% when using pulley systems. This efficiency minimizes worker fatigue and increases productivity.

Though pulleys offer numerous advantages, challenges remain. For instance, improper installation can lead to malfunctions. Regular maintenance is essential yet often overlooked. Some users might not recognize the need for proper alignment and load balancing. These oversights can lead to accidents or inefficiencies. Understanding these nuances is important to maximize the benefits of pulleys in everyday applications.

The use of pulley trolleys in heavy lifting operations greatly enhances safety. A recent industry report highlighted that about 30% of workplace injuries are related to manual lifting operations. Trolleys can reduce the physical strain on workers. This means fewer back injuries and muscle strains. When lifting heavy loads, proper equipment is essential.

In addition to reducing injuries, trolleys improve operational efficiency. Research shows that tasks completed with trolleys are faster and require fewer workers. This is a significant boost in productivity. However, it is crucial to train employees on proper usage. Misuse can lead to accidents. About 15% of accidents occur due to improper equipment handling. Continuous training and assessment are necessary to prevent these issues.

Another concern is the maintenance of pulley systems. Regular checks are vital for safety. A malfunctioning trolley can cause serious injuries. Reports indicate that about 10% of workplace incidents are due to equipment failures. Workplaces need to establish strict maintenance protocols. Ensuring that trolleys are in optimal condition is non-negotiable for safety.

Pulley trolleys are essential in various industrial applications. Their cost-effectiveness is a critical advantage. By reducing manual labor, companies can save on labor costs. This can lead to increased productivity and reduced downtime. Often, businesses can achieve more with fewer resources.

Investing in a trolley system can seem expensive initially. However, the long-term savings make it worthwhile. These systems minimize wear and tear on workers. They also reduce the risk of injuries, which can incur high expenses. Companies must consider these factors when assessing their overall costs.

Despite the advantages, businesses sometimes overlook the need for regular maintenance. A neglected trolley system can lead to inefficiencies. Regular inspections are necessary to ensure optimal performance. In some cases, this oversight can result in costly repairs. Balancing cost with proper upkeep remains a challenge.

Pulley trolleys are tools that simplify lifting tasks in a variety of daily activities. Their versatility is remarkable across different sectors, from construction to home maintenance. A study from the International Journal of Engineering revealed that using pulley systems can increase lifting efficiency by up to 30%. This boost helps save time and reduces the risk of injuries.

People often overlook the practicality of pulley trolleys in personal projects. They can be useful for hanging heavy items, moving furniture, or assisting in renovation tasks. A home improvement report highlighted that 40% of DIY enthusiasts find pulley systems beneficial for reducing effort during their projects. However, it's essential to assess the weight limits and compatibility with materials.

Tips: Always double-check the weight capacity of your trolley. Use a pulley system that matches your specific task. Consider investing in a quality trolley, as durability is crucial. It's easy to underestimate the importance of the right equipment, leading to potential frustrations. This reflects a common oversight—underestimating the need for a proper setup before starting a task.